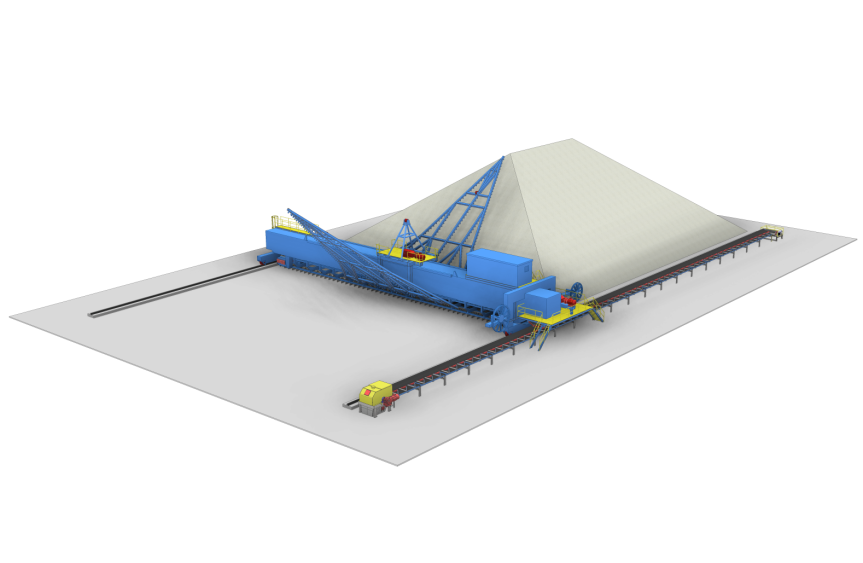

Homogenizing bridge stacker

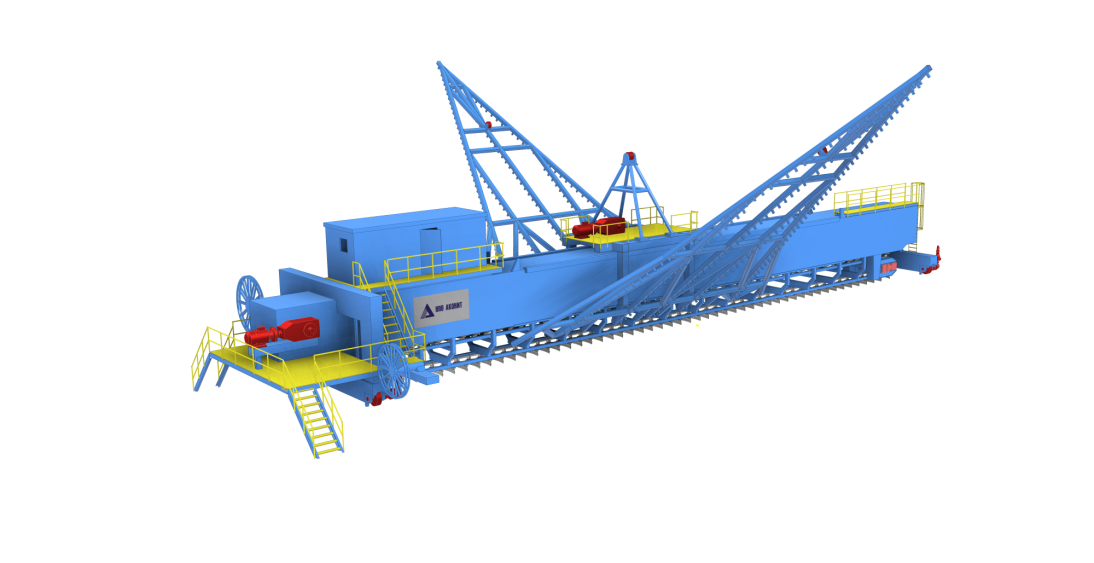

When using a side stacker with a stationary or inclined boom, as well as in covered warehouses with a top loop tripper, the material is continuously deposited in one or more longitudinal stockpiles, which ensures a high level of homogenization. The bridge reclaimer, moving in the longitudinal direction, reclaimes the stockpile with the help of a harrow moving from side to side, which knocks down the product at a natural slope angle under the scraper mechanism located at the zero level of the stockpile. Further, the product is fed by buckets into the discharging chute and enters the belt conveyor, which is installed along the length of the entire stockpile.

This type of storage with a bridge scraper reclaimer is applied in cement plants using dry process. Such a reclaimer is also used at coal-fired power plants. With large-capacity storages for ores, pellets, with a fraction from 0 to 200 mm, bridge reclaimers are used with a rotary bucket wheel instead of a chain with scrapers. Such reclaimers are used for a period of materials storage for about 30 days, the equipment is designed for high capacity from 1500 t/h.

Engineers of "Akonit" make the necessary calculations and modeling of stockpiling and reclaiming processes.