Feeders

The feeders are intended for uniform feeding from the hopper to different inlet devices: conveyors, periodical transport means, etc.

Belt feeder

Its working body is a rubberized-fabric conveyor belt bending around driving and tension pulleys. Stationary bolts are located above the upper belt run resting on rollers or fixed metal decking. The control damper allows changing the feeder capacity. The calculation of belt feeders is equivalent to the calculation of belt conveyors. Feeder belt speed is 0.05–0.45 m/s.

Apron feeder

There is a decking made of steel plates overlaying each other and attached to links of two pull chains which are driven with driving sprockets. The required tension of chains is created with a screw tensioning device connected to the axis of chain idlers. The chains are equipped with rollers which roll along the guide slides. The feeder capacity is regulated with a flat slide valve. The speed of plate decking motion is 02.02–0.25 m/s, coefficient of charge is 0.8. The calculation of these feeders are done according to the diagram of the apron conveyors.

Chain feeder

It has a set of endless chains (working body) hanging in the front of the hopper inlet and forming a heavy curtain preventing the spontaneous discharge of bulk load from the hopper. The chains move by means of the driving pulley and discharge the load. The feeder capacity can be adjusted by changing the pulley rotational speed.

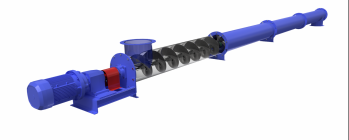

Screw feeder

Feeds the bulk load by means of rotating screw. The advantage of these feeders is their leak-tightness and the disadvantage is a high-speed wear of screw and tray as well as a high energy consumption. The capacity is regulated with a change in the screw rotational speed or with a gate valve in the hopper neck.

Disk feeder

Has a horizontal disk which rotates above the hopper inlet. The scraper is installed on the side above the disk, it discharges the bulk load from the disk to the inlet device.

Pulley feeder

Has a cast iron pulley with the diameter of 300–1200 mm located above the hopper neck. When the pulley rotates the bulk load is discharged from the inlet at a speed of 0.025–1.0 m/s.

Rotary vane feeder

Consists of a housing divided by vanes into compartments. When the housing rotates the fine size material is fed from the hopper with high accuracy.

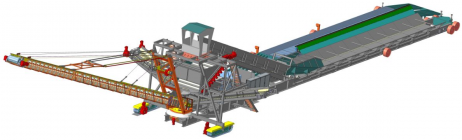

Advantages:

- Takes out large amounts of load from under the hopper

- Lumps of different sizes: from watered ground to stones

- Used to clear any debris

- Slow and very powerful conveyor

Отрасли применения продукции