Rollers production

Производственная площадка НПО «Аконит» по выпуску роликов для конвейеров расположена в Татарстане. Ее мощность — 1 млн. комплектующих в год. Отличительные особенности роликов: повышенный ресурс службы и возможность работать в сложных условиях эксплуатации (ролики тяжелой серии). Полностью ассортимент роликов представлен в разделе «Продукция»

Что помогает обеспечить качество продукции на заводе конвейерного оборудования?

Завод был открыт в 2020 году. Он оснащен современным станочным парком, а в производстве роликов для конвейеров применяются технологические решения, разработанные специалистами НПО «Аконит». Они запатентованы, в том числе конструкция защитного узла подшипника (лабиринтное уплотнение). В изготовлении ролика для конвейера ставка сделана на простоту конструкции и улучшенные характеристики изделия: радиальное биение, осевой люфт, момент сопротивления вращению.

Контроль качества осуществляется на всех производственных этапах, начиная с тщательного подбора поставщиков сырья и заканчивая межоперационным контролем заготовок и готовых деталей: на участке резки трубы, штамповки, обработки осей. Все детали проверяются на соответствие ГОСТ. Производство конвейерного оборудования полностью автоматизировано. Блок сварки оборудован 4-мя роботами. Автоматическая линия правки и калибровки круга применяется для калибровочных операции с целью улучшения характеристик исходного проката круга: кривизна, овальность, чистота поверхности. Вырубка диска из листа и его последующая штамповка до формирования детали «корпус подшипника» осуществляется с помощью пресса, где задействована система размотки рулона и подачи в зону вырубки, системы автоматического перемещения заготовок.

Механическая обработка осей производится на токарных обрабатывающих станках (Китай) с центральным шпинделем и двумя револьверными режущими головками. Обработка шеек осей происходит одновременно с двух сторон, что обеспечивает идеальную соосность посадочных мест под подшипники.

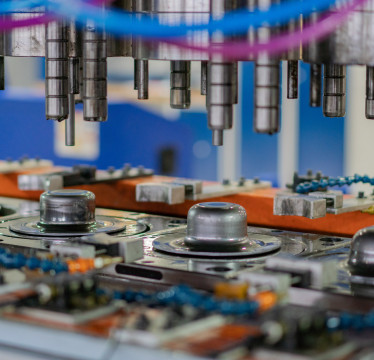

На блоке сборки ролика происходит сборка сваренной с корпусами подшипников трубы с остальными комплектующими ролика: ось, подшипник, лабиринтные уплотнения - с последующим автоматическим контролем выходных параметров ролика.

Покраска роликов конвейерных: нанесение лакокрасочного покрытия на ролики и последующая их сушка осуществляются в специальной камере. Камера оборудована роботами на погрузку и роботами на покраску.

Готовая продукция укладывается на европаллеты, производятся обвязка ошиновочной лентой и обмотка стрейч-пленкой. Автоматизированное производство, постоянный контроль и использование собственных технологических разработок позволяют предлагать рынку ролики с ресурсом службы 45 тыс. часов.

Это обусловливает стоимость роликов для конвейера, которая полностью компенсируется за счет снижения расходов на обслуживание оборудования и потерь, которые компания могла бы понести во время ремонтного простоя. В перспективе 6 лет снижаются расходы и на приобретение самих роликов, так как их нужно менять в 2 раза реже.

НПО «Аконит» также разработал и выпустил на рынок ролики тяжелой серии. Эти комплектующие предназначены для протяженных конвейерных систем (более 1 км) и сложных условий эксплуатации. Такие ролики для конвейера могут эффективно работать в условиях низких температур, обмерзания. Они обеспечивают бесперебойное движение конвейерной ленты, минимизируя риски простоя конвейерного оборудования. В тяжелой серии выпускаются ролики различных видов. Сроки изготовления зависят от требований заказчика, количества роликов ленточного конвейера в партии, а также логистики.