Advanced technologies of the industrial automation

Направление промышленной автоматизации производства развивается в компании более 6 лет. Сформирован штат высокопрофессиональных специалистов, которые ведут проектирование с учетом самых высоких требований клиентов по выбору комплектующих и организации логики управления. Проектирование осуществляется в программе EPLAN Electric P8, что обеспечивает автоматизацию процесса проектирования и снижает влияние человеческого фактора, в дальнейшем планируется интеграция среды EPLAN с CAD PLM/PDM и ERP-системами.

Главное преимущество для заказчика – оптимальное соотношение цены и качества при решении поставленных задач. Компания осуществляет выполнение проектов «под ключ», начиная от услуг технического аудита до непосредственного ввода оборудования в эксплуатацию и при необходимости последующего сервисного обслуживания. Для ведения деятельности имеются все необходимые разрешения и свидетельства.

Мы предлагаем услуги промышленной автоматизации не только конвейерного оборудования, а также решение инжиниринговых задач в области автоматизации технологических процессов и производств любых промышленных объектов.

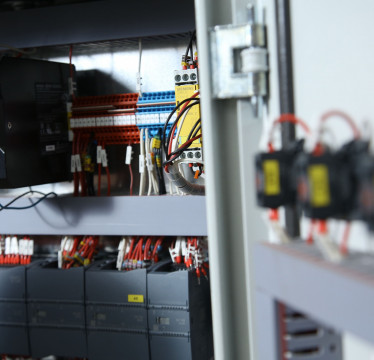

НПО «Аконит» является партнером компании Siemens, Schneider Electric, ABB, Omron, Danfoss и других мировых лидеров в сфере автоматизации. Компания имеет собственный участок для сборки щитовой продукции и обеспечивает высокий уровень качества сборки шкафов. Перед отправкой в обязательном порядке вся щитовая продукция проходит имитационные испытания, в тестовом режиме устраняются выявленные недочеты схем и программного обеспечения, что в последующем гарантирует быстрый ввод в эксплуатацию.

Наш опыт

За 6 лет автоматизировано более 450 единиц оборудования, в том числе: конвейеры ленточные, винтовые, крутонаклонные, дробилки конусные, валковые и щековые, грохоты, вибропитатели, качающиеся питатели, питатели пластинчатые, насосы, плужковые сбрасыватели, шиберы, затворы и другое технологическое оборудование.

Основные заказчики автоматизации: АО «Апатит» (холдинг «ФосАгро»), АО «Северо-Западная Фосфорная Компания», ПАО «Акрон», ПАО «Полюс», ПАО «Северсталь».

Услуги отдела АСУ ТП:

- предпроектное исследование

- подготовка ТЗ для заказчика

- расчет и проектирование оборудования

- программирование PLC- и HMI- панелей

- разработка SCADA-систем

- сервисное обслуживание, ремонт, монтаж и пусконаладка на всех этапах внедрения оборудования

- обучение специалистов

Преимущества внедрения автоматизации на предприятии:

- экономия потребляемых энергоресурсов

- контроль и оптимизация регулирования технологических параметров

- снижение доли ручного труда в технологическом процессе

- улучшение качества обслуживания оборудования

- повышение качества выпускаемой продукции

- повышение показателей безопасности на производстве

- своевременное и точное представление информации руководителям всех уровней