Stockpiling technologies

SIA "Akonit" - your competence center for the transportation, stockpiling and handling of bulk cargo

Carefully selected and designed by our specialists, the equipment makes it possible to maintain the quality of the manufactured product throughout the entire cycle of storage and handling.

JSC "SIA" Akonit " has been a comprehensive supplier for many years of both technological lines and individual machines in the mining, cement, chemical industries, and port facilities.

The equipment produced by our company meets the high requirements of the customer and is designed for operation in hard conditions.

Двигаясь вдоль штабеля, борона осыпает материал под углом естественного откоса на скребковый механизм. Так происходит эффективное усреднение продукта.

Данная технология разработана специально для усреднения липких материалов - таких как глина, шихта и прочие продукты, чаще используемые в цементной и керамической промышленности.

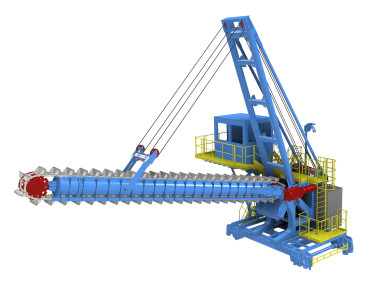

Технологическое решение с боковым реклаймером является экономически эффективным для малых и средних производств, так как заменет технологию с грейферным краном.

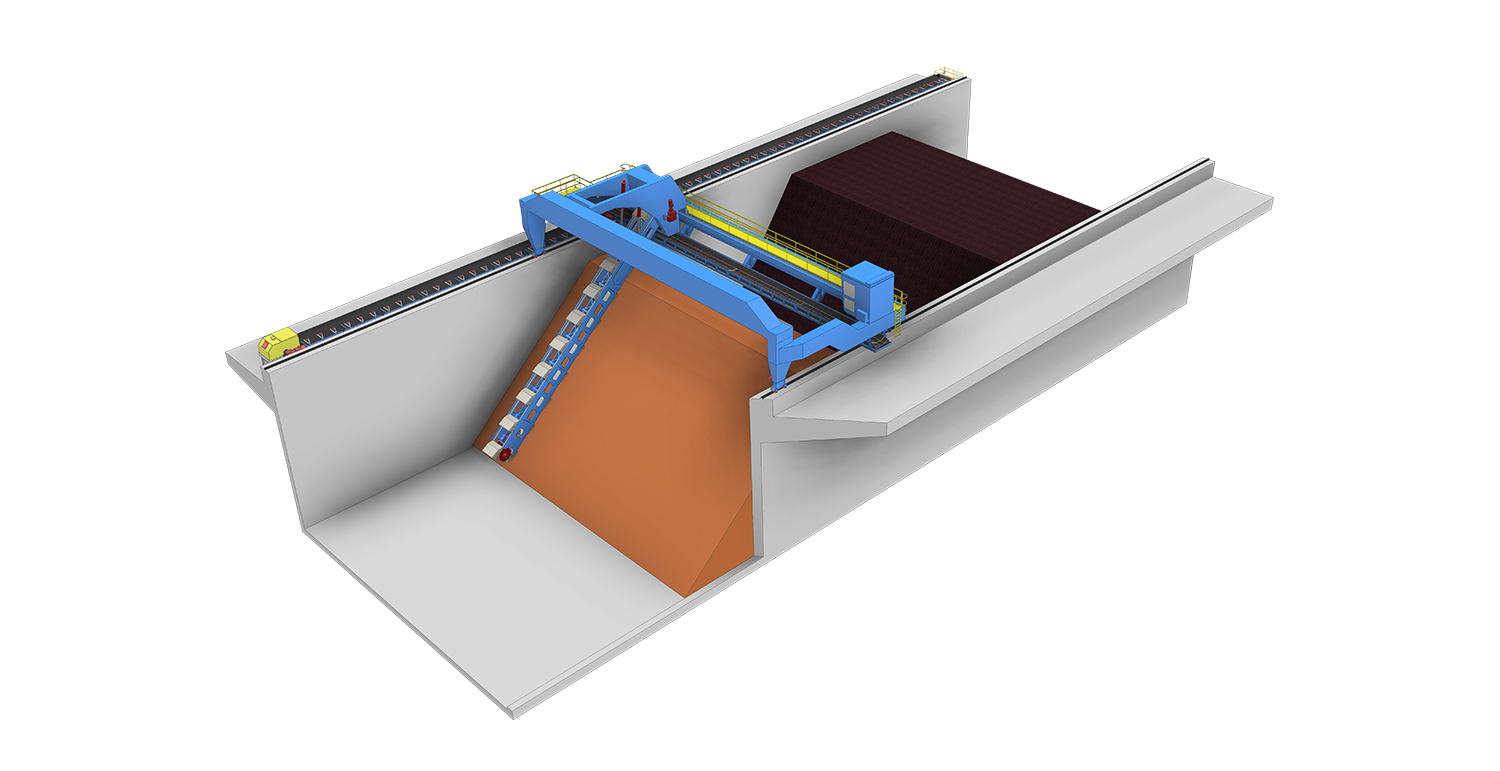

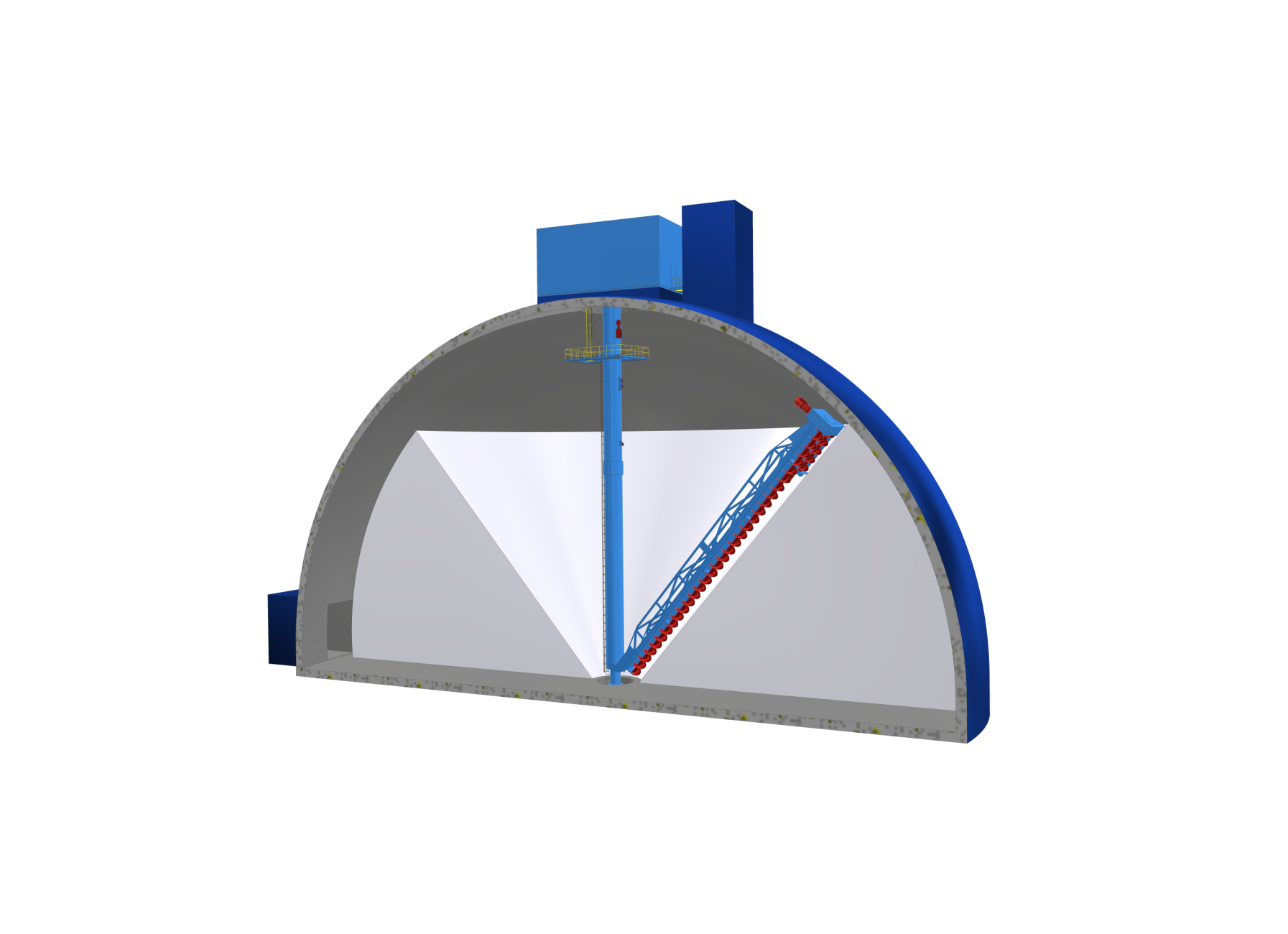

Основная конструкция реклаймера поворачивается на 360 градусов, перемещаясь по рельсам в продольном направлении склада, и разбирает штабель на подземный конвейер.

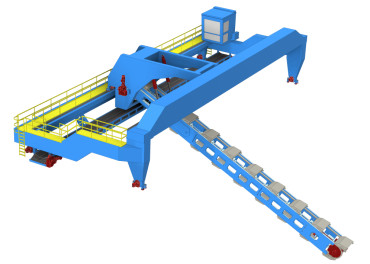

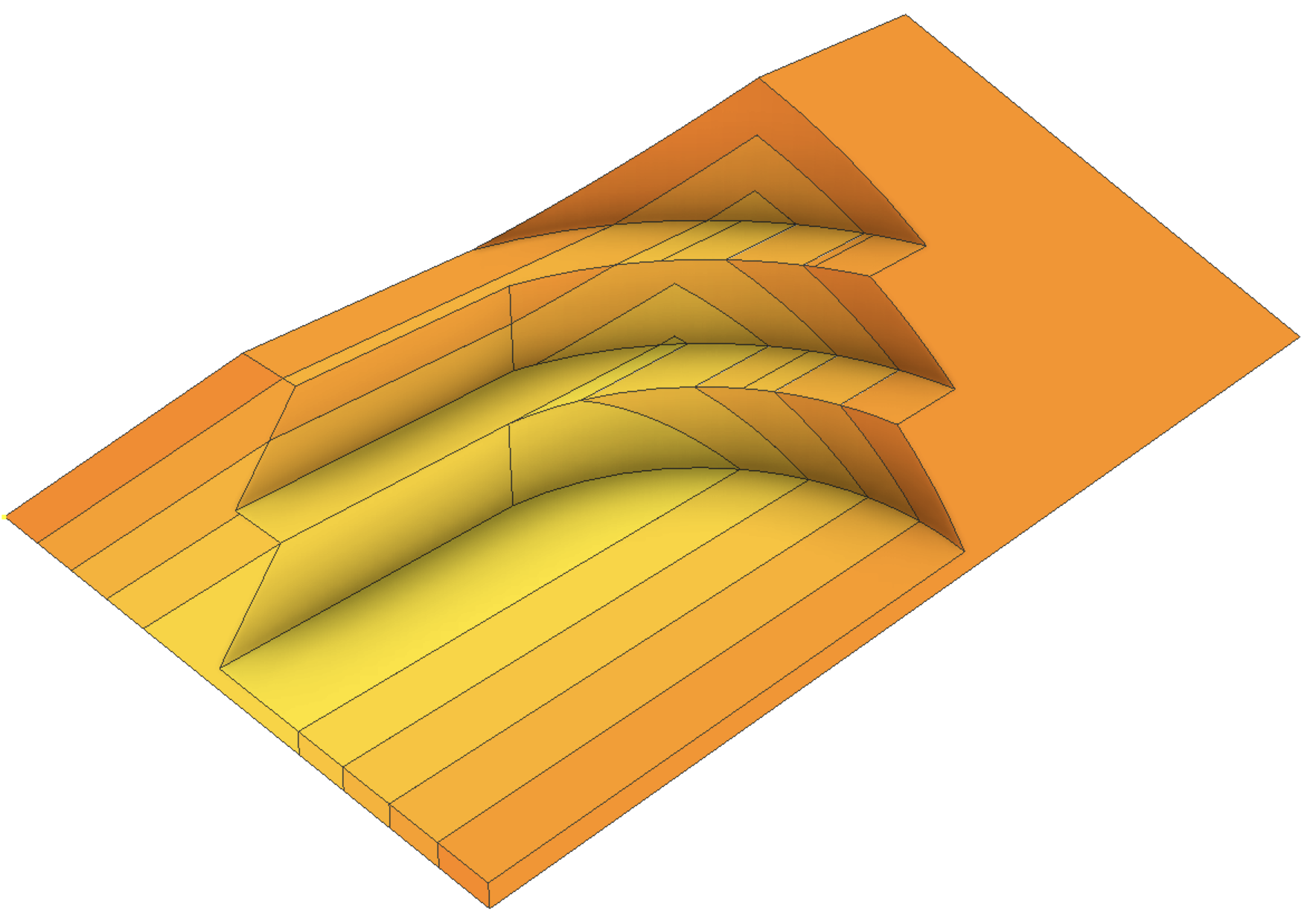

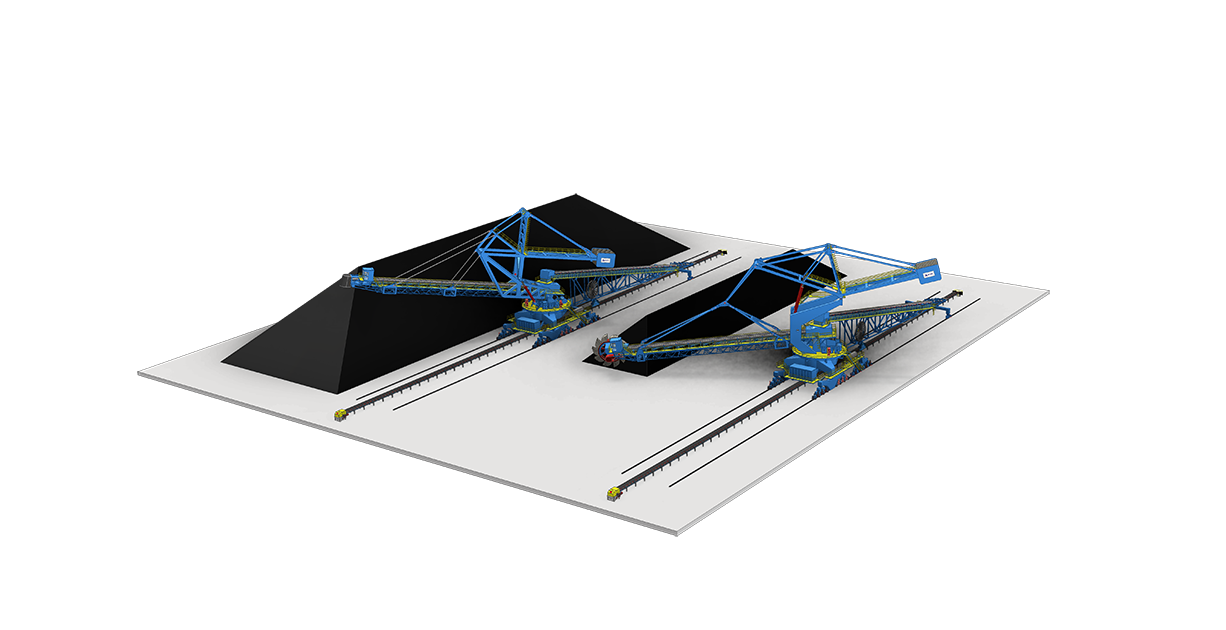

Полупортальные реклаймеры являются самыми распространенными и технологически гибкими машинами для складирования продукта разной фракции и химического состава.

Инженерами НПО "Аконит" разработаны несколько модификаций, каждая из которых учитывает особенности транспортируемого материала, производительность и геометрию склада.

Конструкция роторного колеса и ковшей позволяет разрабатывать известковые и меловые карьеры, работать с высоко абразивными продуктами на производственных складах.

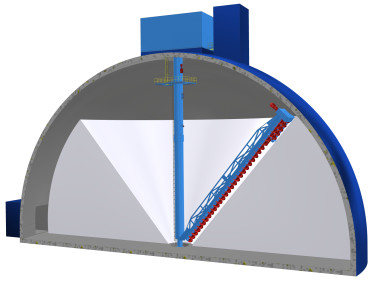

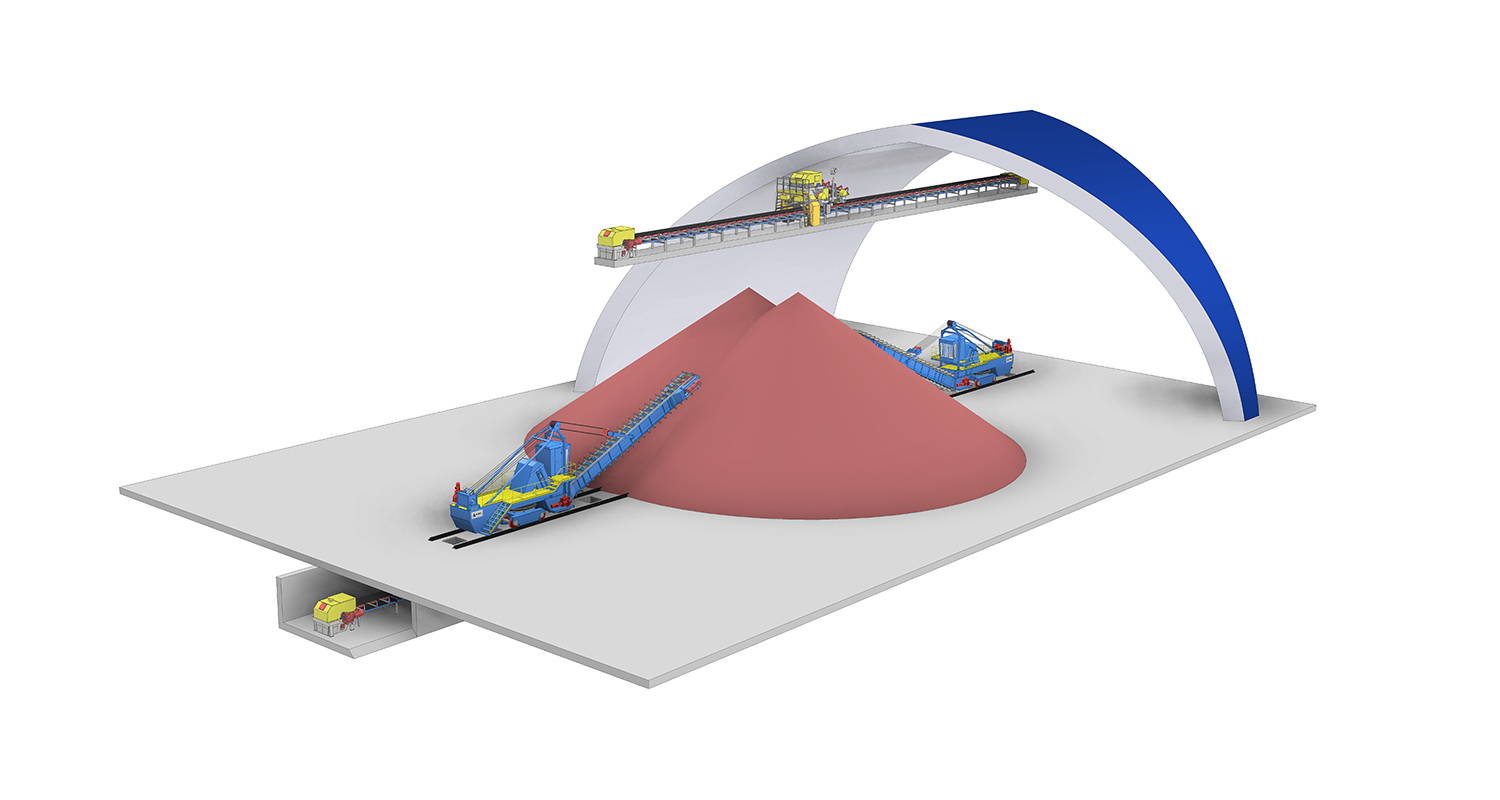

Учитывая склады купольного и продольного типов, а также силосов, разработаны несколько видов винтовых реклаймеров для минеральных удобрений, древесной щепы и сельхозкультур.

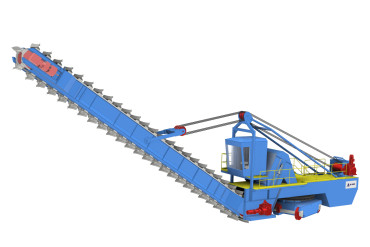

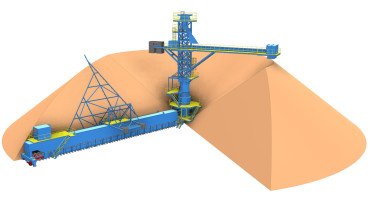

Combined portal stacker-reclaimer is used when it is necessary to simultaneously load and unload a warehouse, this allows to reduce capital and operating investments.

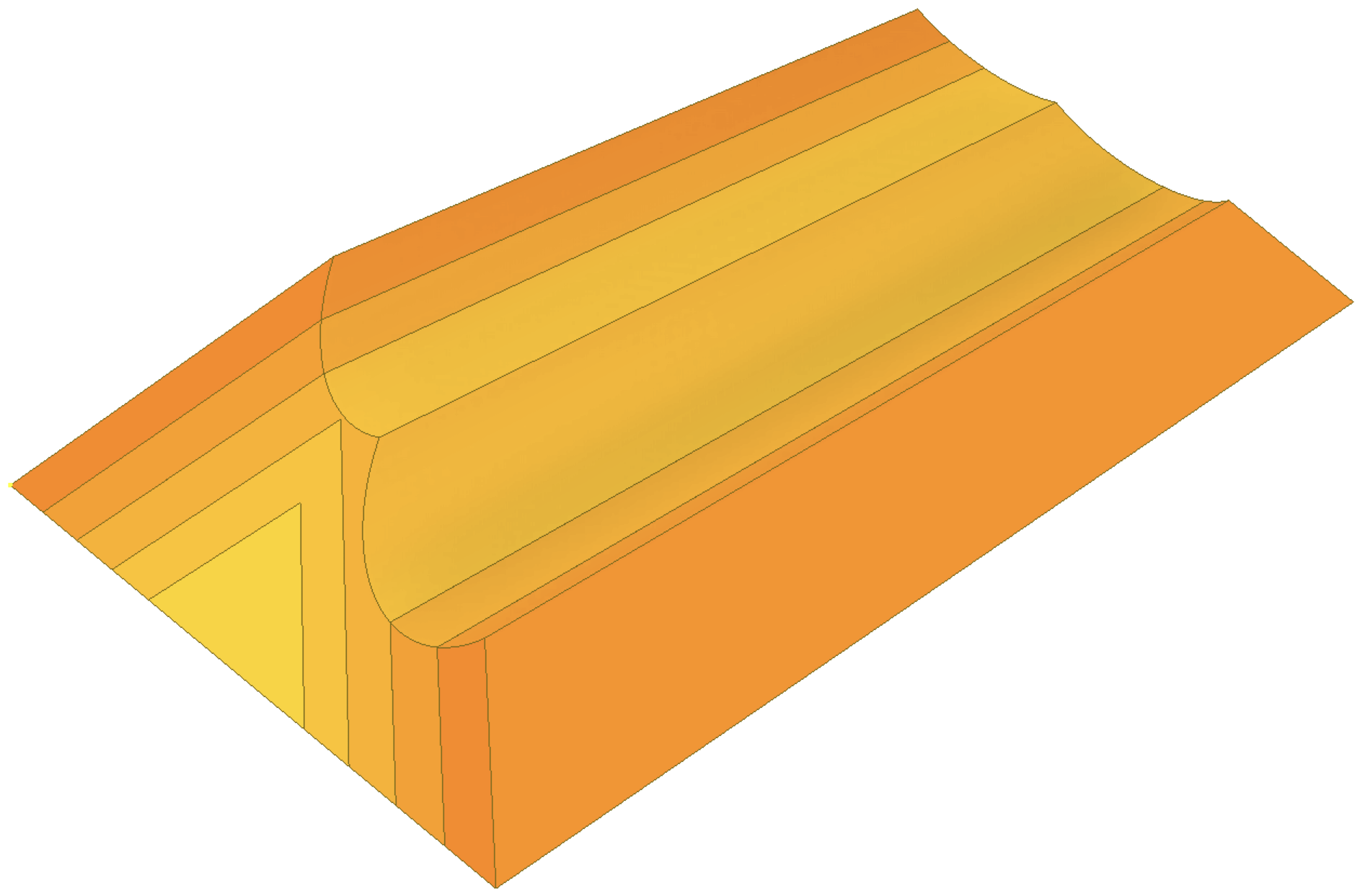

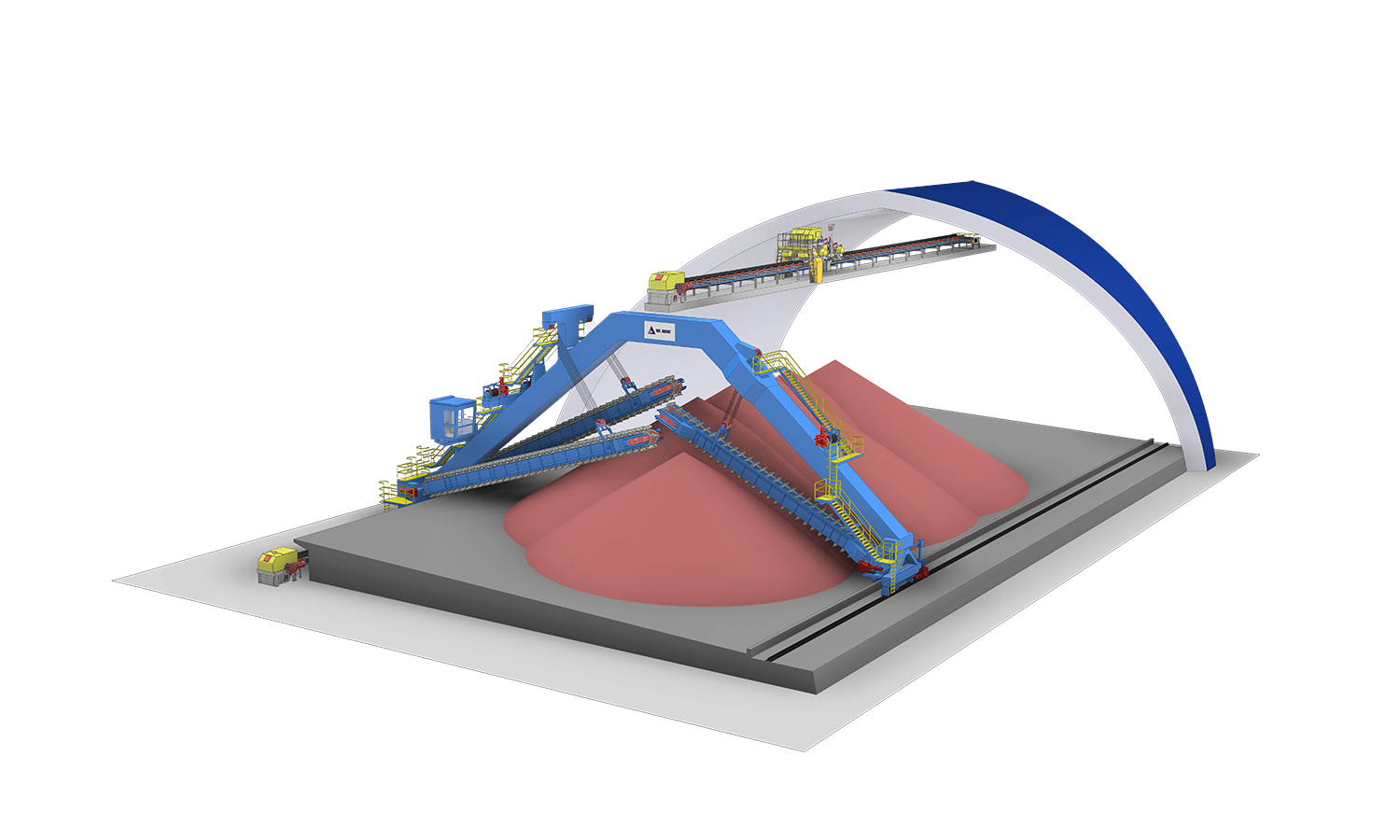

Chevron's radial stockpiling and material reclaiming system ensures good mixing and homogenization of the product.

It is used in port facilities for coal handling, at metallurgical enterprises for storage of iron ore, hot-bracketed iron and other products.

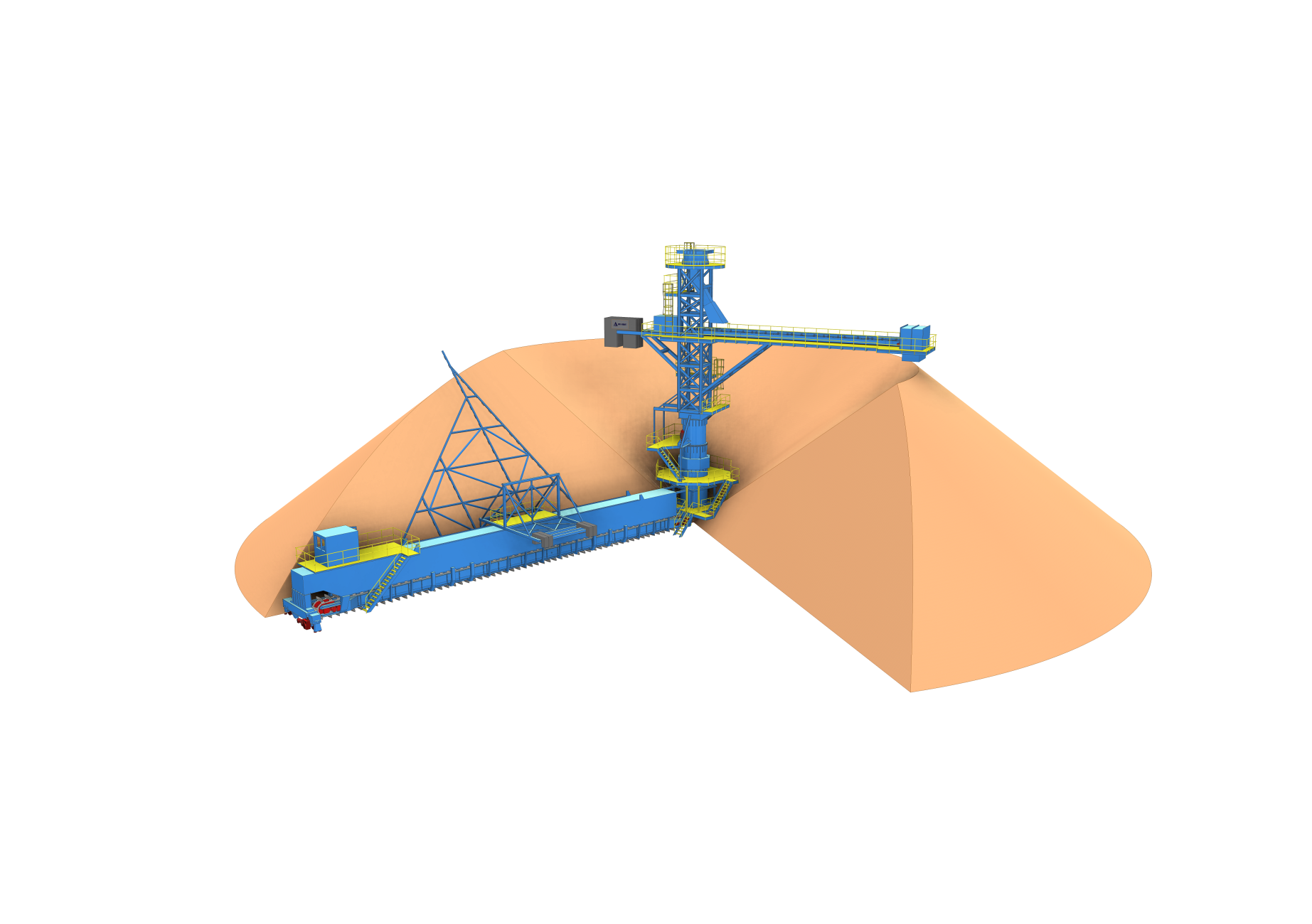

The use of radial spreaders on rails or pneumatics with a lifting and retractable boom allows the formation of stationary and dynamic stockpiles.

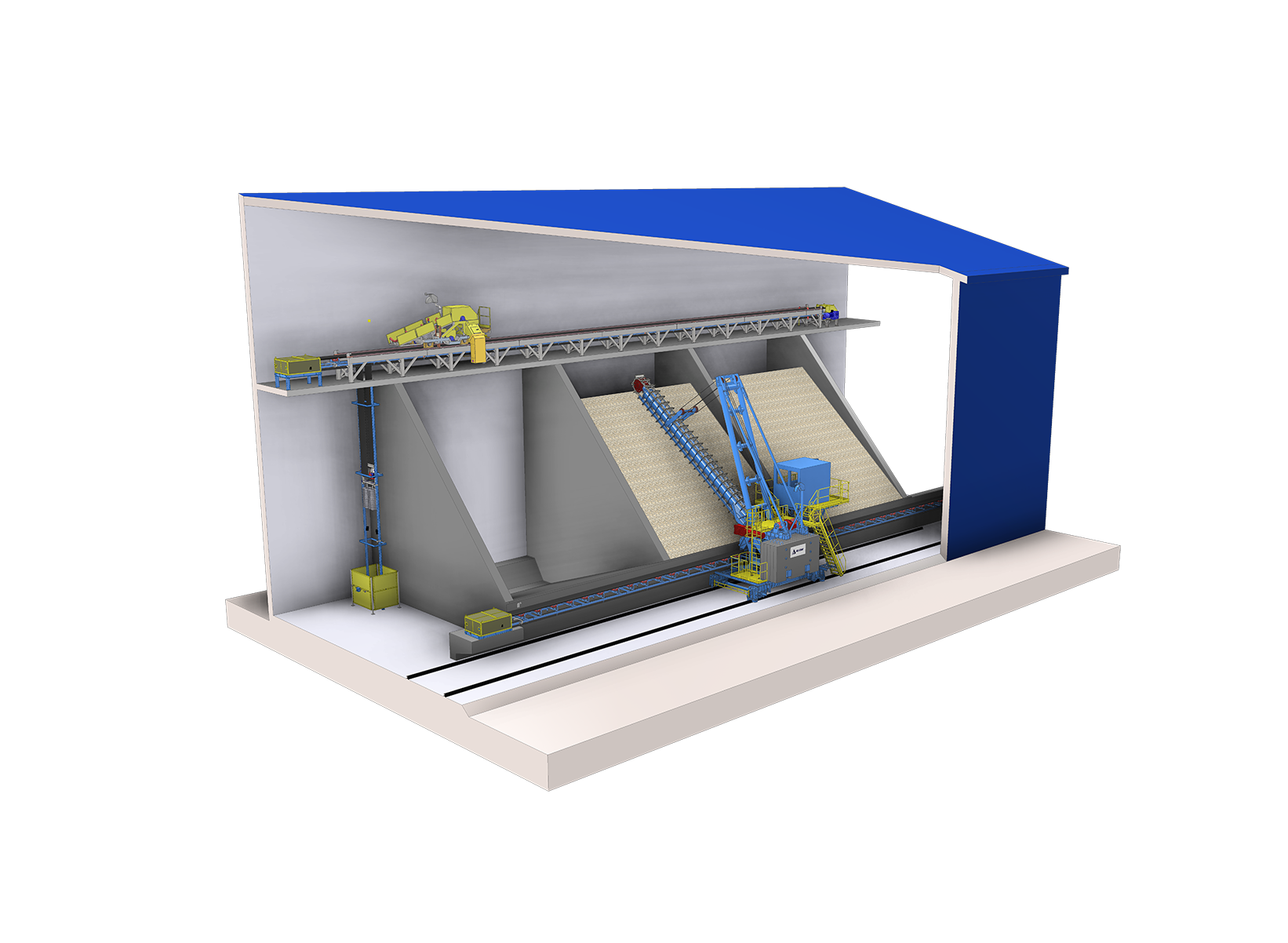

The top loading of the warehouse is carried out by a retractable belt conveyor or a loop belt conveyor. The equipment is reliable and cost effective.

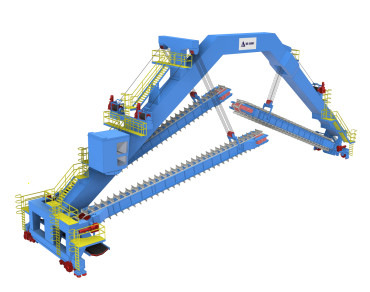

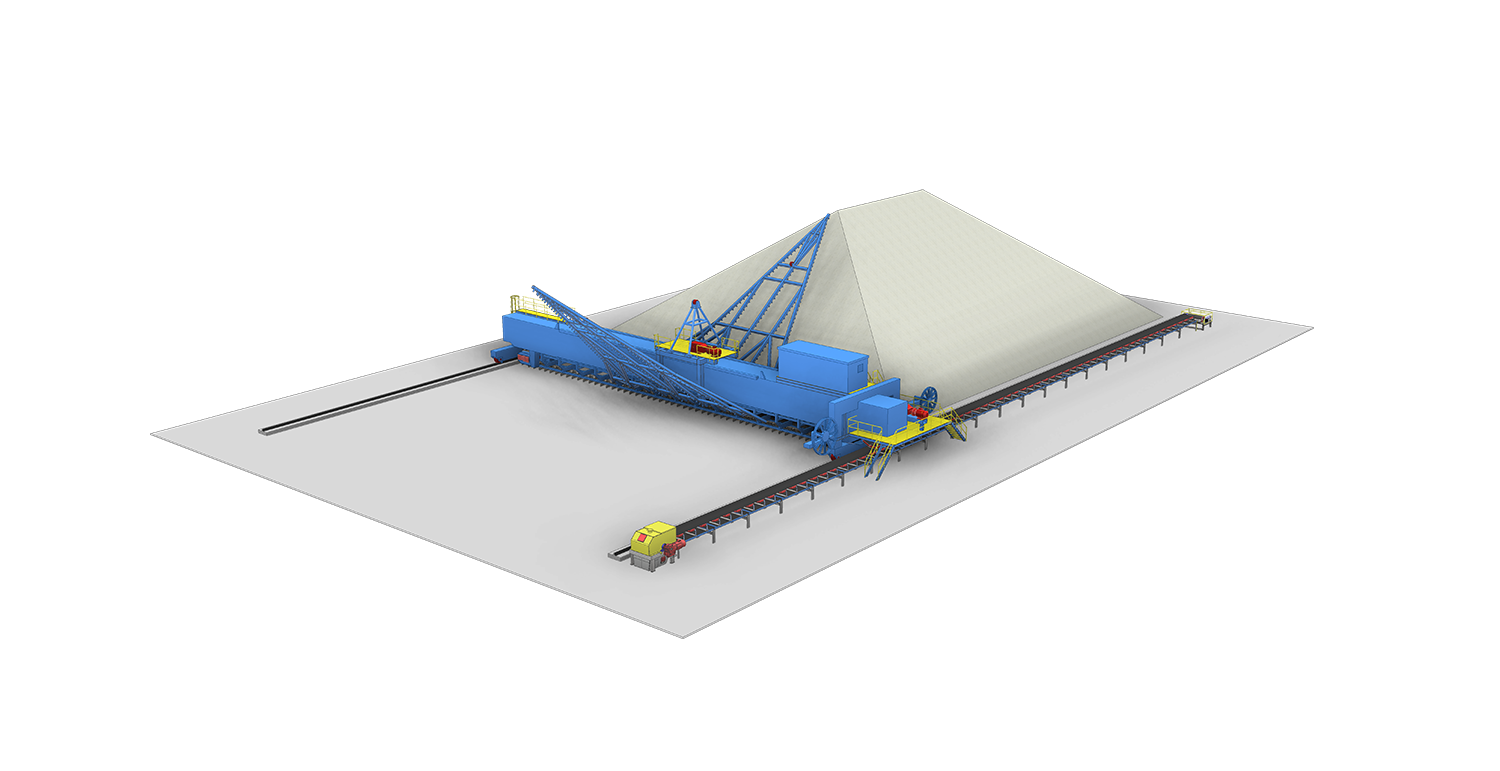

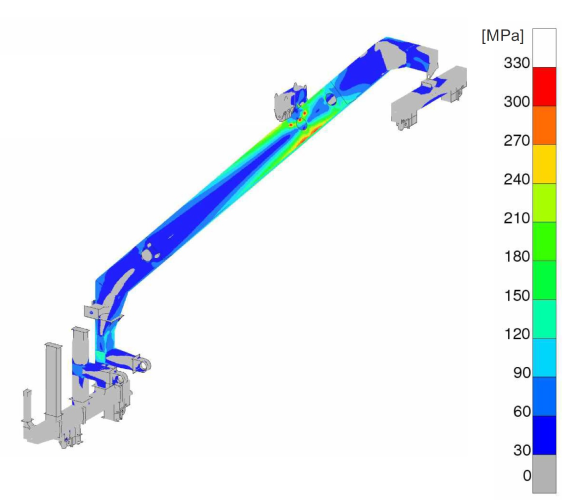

Stackers are of one or two boom construction with slewing and luffing mechanism with winches or hydraulic cylinders.

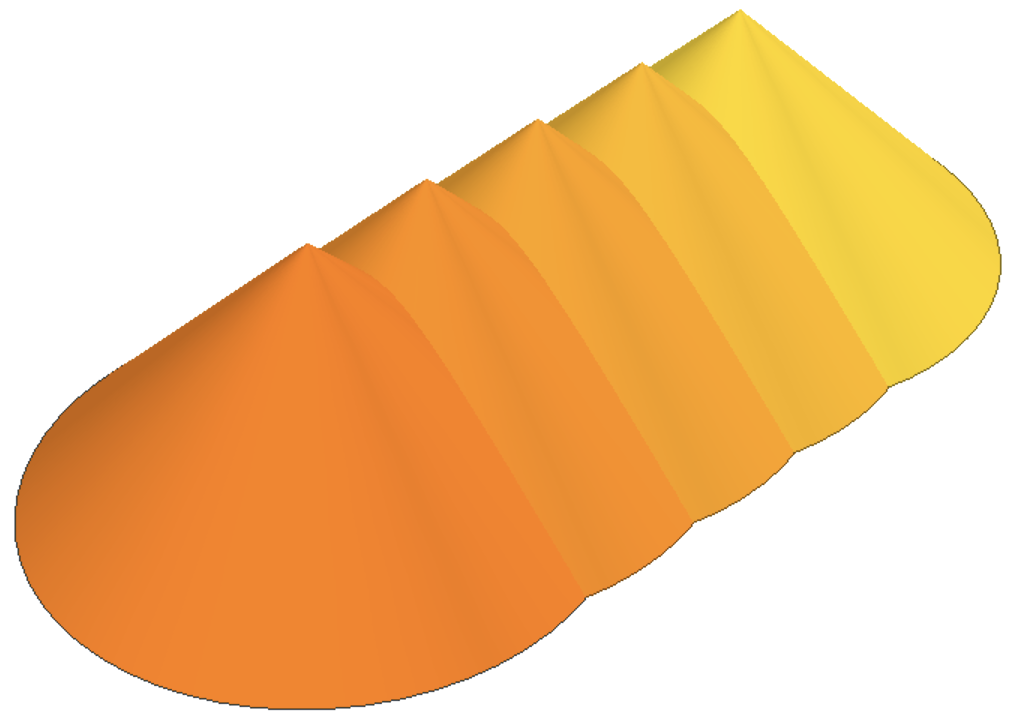

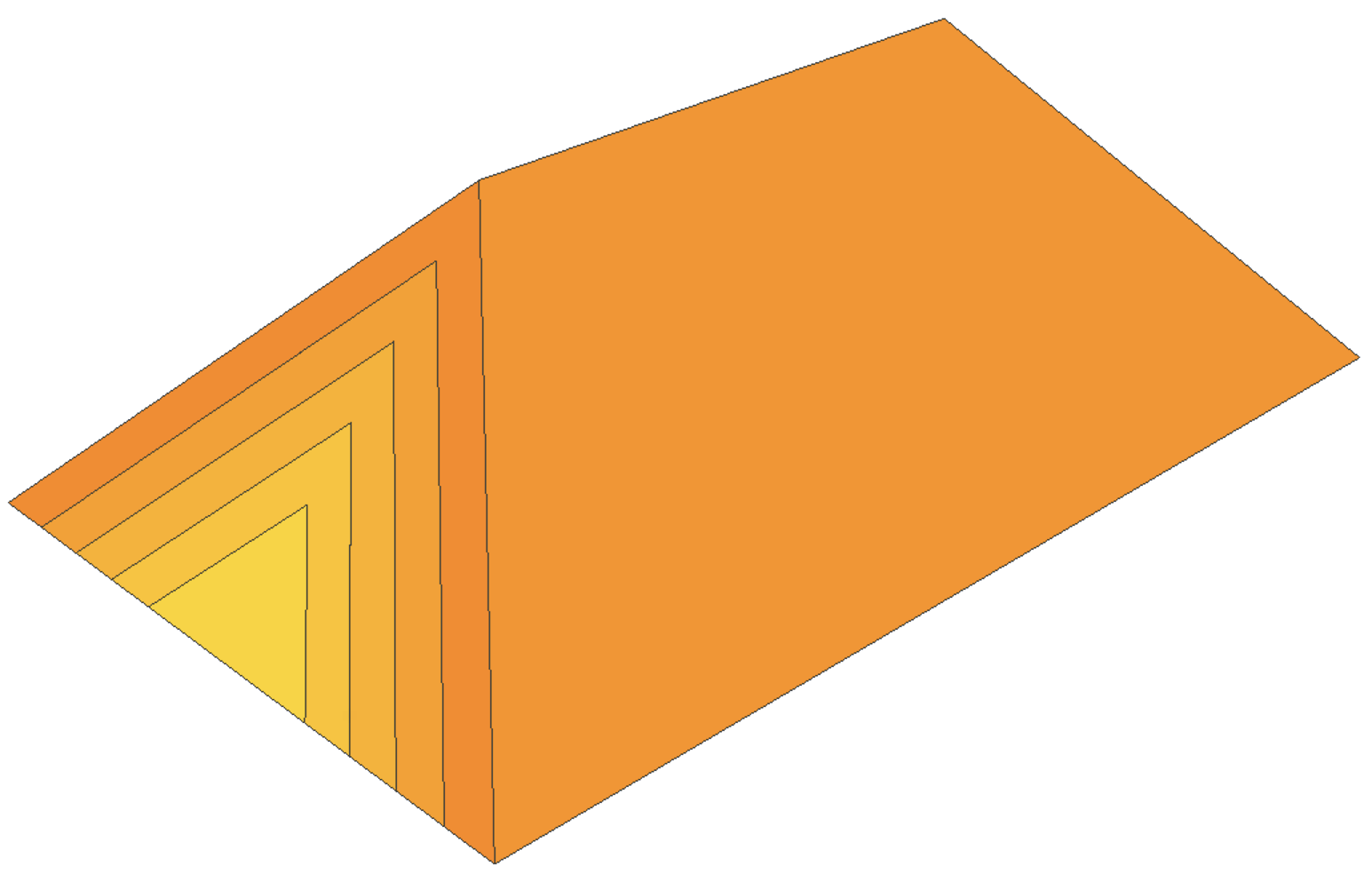

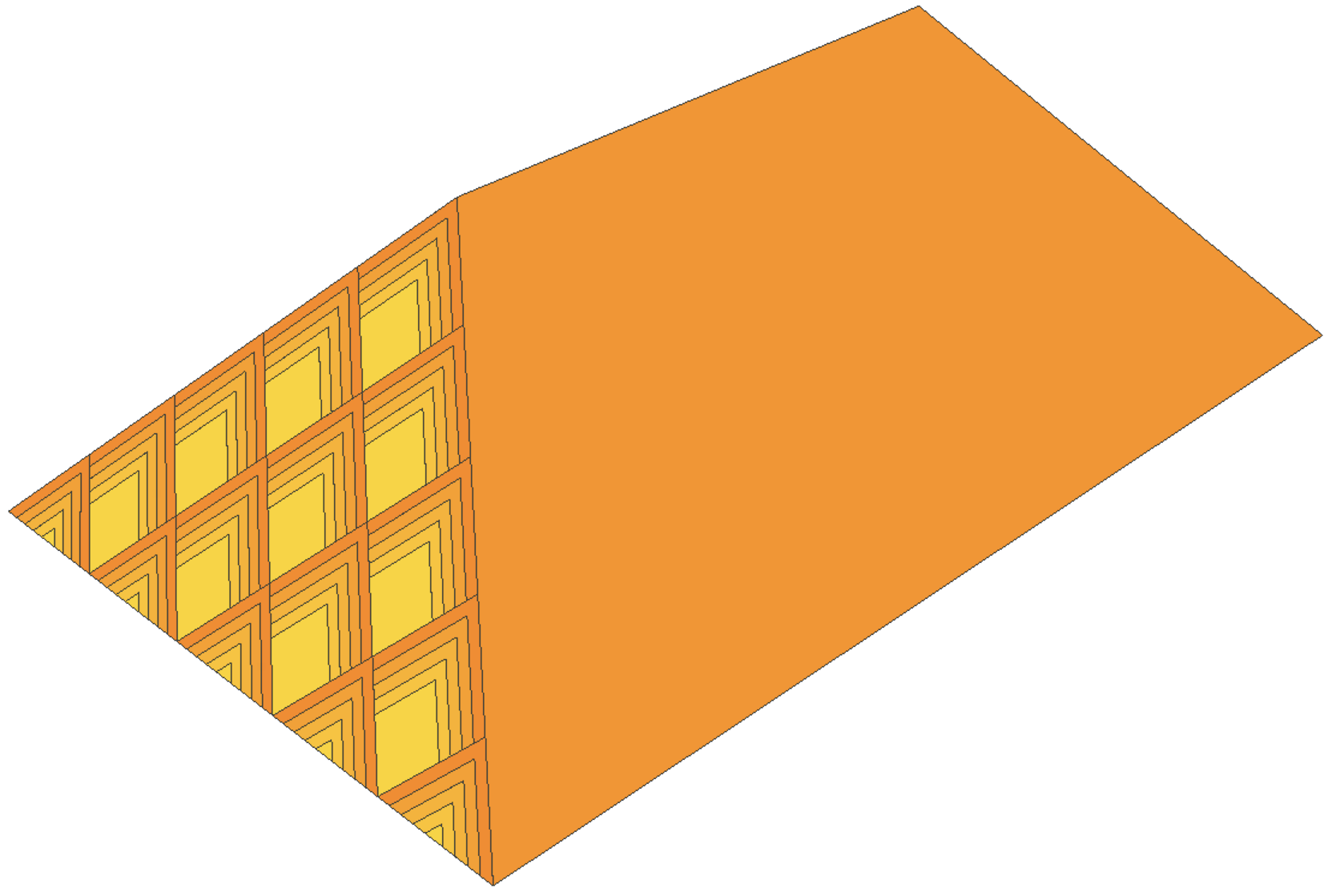

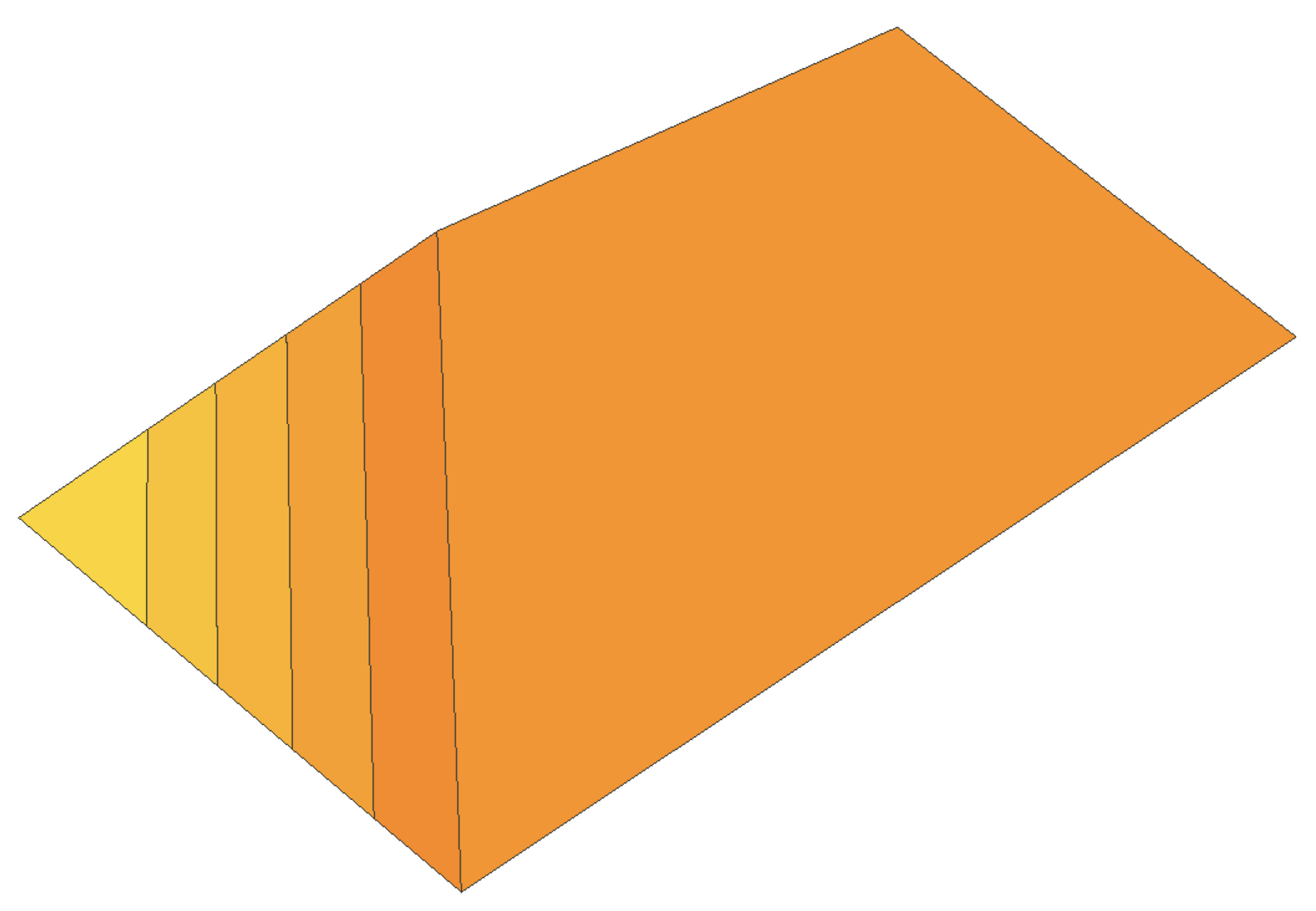

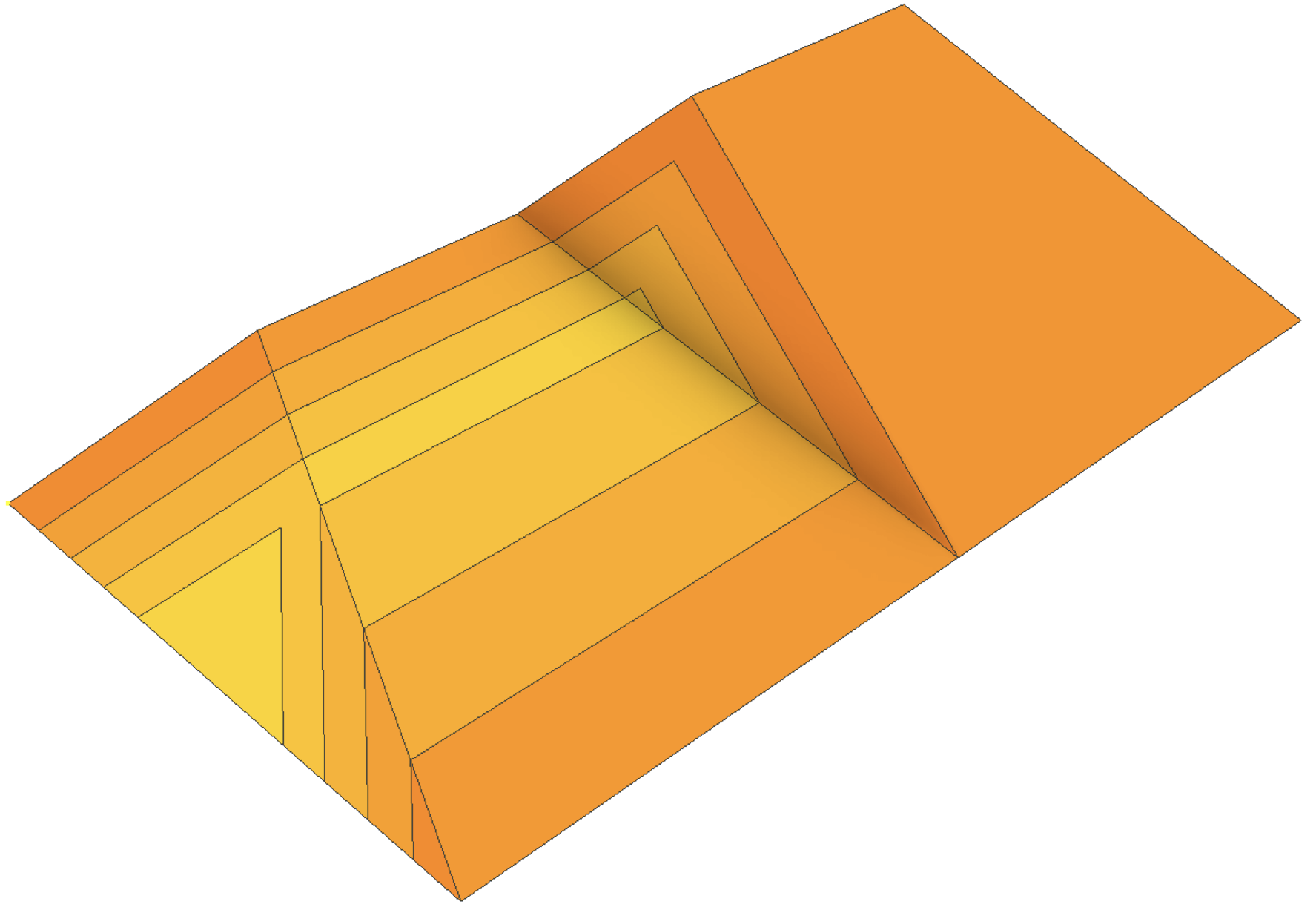

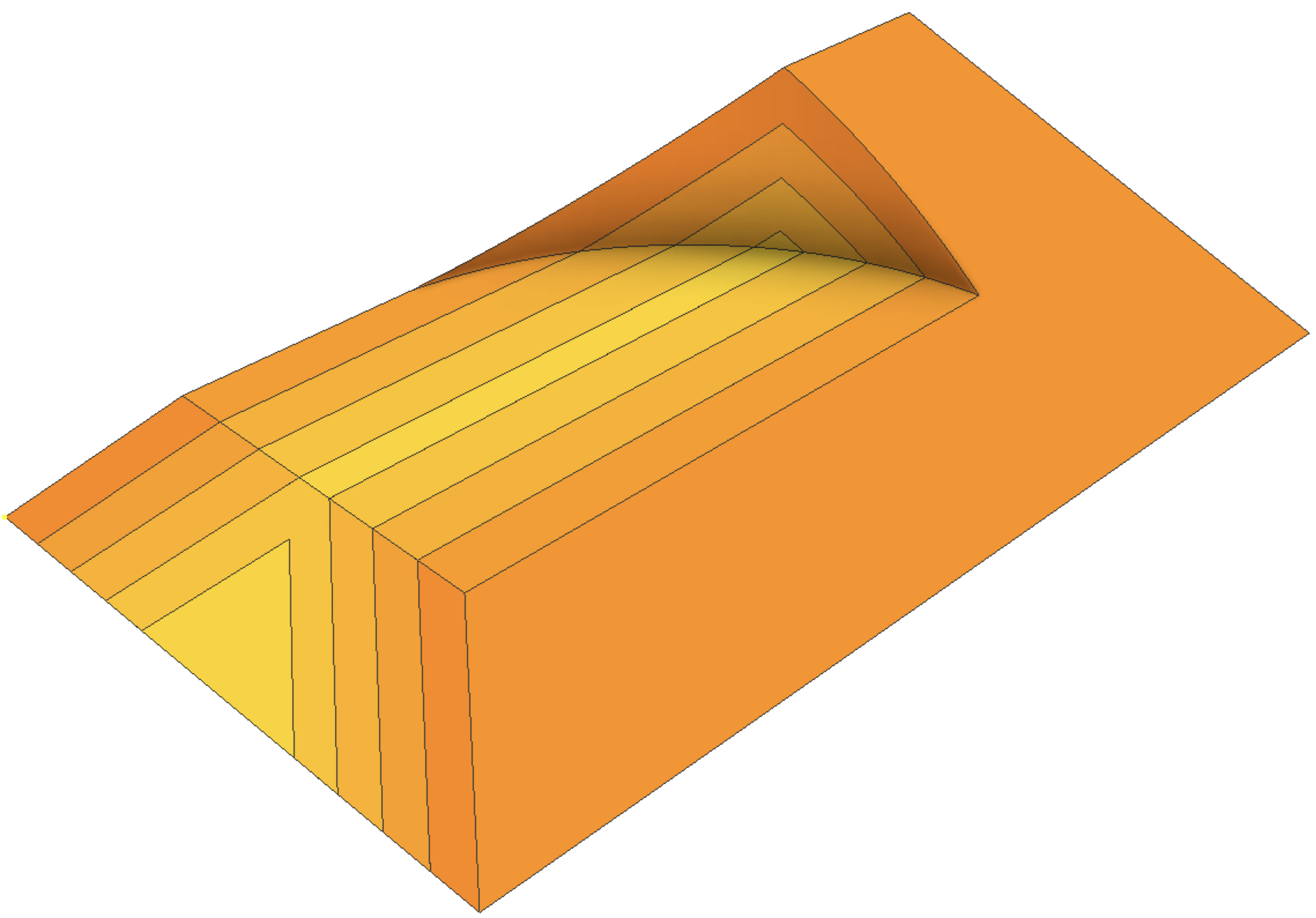

Cone Shell, Chevron, Window, Strata — наиболее распространенные методы накопления. Слои укладываются друг на друга по направлению штабеля, создавая эффект перемешивания продукта. ООО «Akonit» производит технологическое оборудование для штабелирования: штабелеры (наклонные, поворотные, двухстреловые), рельсовые ленточные конвейеры, петлевые сбрасыватели, мобильные гусеничные и пневматические разбрасыватели.

Рекультивация имеет большое технологическое значение. Реклаймеры производства ООО Akonit обеспечивают необходимую степень гомогенизации материала, постоянную производительность в сочетании с низкими эксплуатационными расходами и высокой загрузкой оборудования. Наши технические решения основаны на опыте работы в различных отраслях промышленности и отвечают высоким требованиям по энергоэффективности, предписанному износу и оптимальному весу реклаймера.

Технологически склады делятся на два типа: гомогенизационные и складские. Хранение сыпучих материалов необходимо в случае сбоев в транспортной системе в шахтах или карьерах, из-за которых материал не может быть отгружен заказчику или передан в производство. Складская мощность варьируется от 7 до 45 дней и рассчитывается индивидуально для каждой производственной линии. Склады могут иметь продольное и радиальное расположение. Радиальный склад имеет компактную площадь. Продольный склад используется из-за большой вместимости и возможности расширения в будущем.

Для каждого типа склада мы разработали специальное оборудование со множеством конструктивных особенностей, вариантов и планировок.

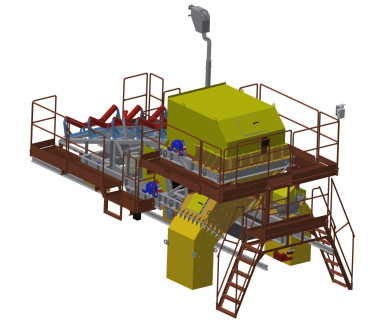

Универсальные реклаймеры совместно с конвейерным транспортом склада предназначены для обеспечения постоянной и равномерной подачи продукта в технологию. Краны Kratzer, изготовленные на современном оборудовании, обеспечивают бесперебойную работу склада. Комплексная поставка автоматизированного складского оборудования гарантирует высокую эффективность и низкие эксплуатационные расходы.

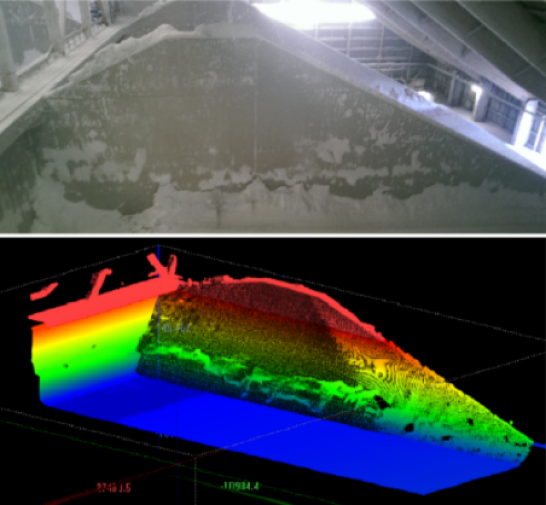

For kratzer cranes of third-party manufacturers, we can manufacture any spare parts according to the drawings of the Client, we also carry out 3D scanning of components with the subsequent development of design documentation and production.