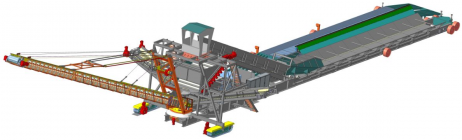

Clamp-forming system

The clamp-forming machine is intended for unloading transport means for sugar beet, cleaning the beet of soil, top, weed plants and for piling the beet. The clamp-forming machine is a maneuvering equipment with optimal sizes thanks to which it is possible to use it at plant beet receiving stations with concrete or compacted ground coating.

Principle of operation: the beet passing through the adjusting gate valve is fed by the belt conveyor to the impurity trap. The separated and free impurities in the beat mass are fed to the chute and then conveyed to the transport and the beat rolls down along the gravity chute to the inlet hopper of the stacker conveyor and then to the pile. The chevron belt of the stacker conveyor is driven by two gear motors which are aligned with the driven pulley in the upper part of the arm.

Advantages:

- Used in the sheltered warehouses

- High reliability of mechanism

- Automated self-propelled packaged system

- Reduces the beet damage during the processing