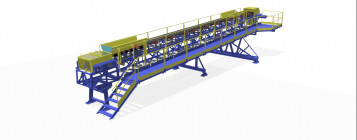

Mobile / rotary belt conveyor

Scope of application of the belt conveyor

The mobile belt conveyor of conventional design with the belt width from 400 to 1600 mm are intended for horizontal and inclined transportation: inclination angle is up to 21° when the flat belt is used and up to 35° when the chevron belt is used.

The conveyors are manufactured in the climatic version U or moderate climate regions as per GOST 15150 in the climatic version T for tropical climate regions as per GOST 15151, environmental class 1 or 2.

The mobile/rail-mounted belt conveyor is used for handling operations and transportation of bulk and lump loads with a density up to 3.2 tons per meter as well as to change the motion direction as a part of the conveyor system. The logistic path is optimized due to the high mobility of the equipment. The mobile/rail-mounted belt conveyor is capable to simultaneously serve more than one line and if necessary it can have a reverse. The wide rotation angle of the belt conveyor — from 45° to 135° — allows to organize the work indoor and at sites of different sizes.

Design versions:

1.1. Extension conveyors (intermediate):

- KLP — mobile belt conveyor;

- KLP-T — telescopic mobile belt conveyor.

1.2. Stacking conveyors:

- KLP-Sh — stacking mobile belt conveyor;

- KLP-ShR — stacking radial mobile belt conveyor;

- KLP-ShRT — stacking radial telescopic mobile belt conveyor.

1.3. Transfer/feeding conveyors (hoppers):

- -KLP-Kh — horizontal feeding conveyor;

- -KLP-KhM — mobile horizontal feeding conveyor.

1.4. Conveyors – truck dischargers:

- KLP-R is a conveyor – truck discharger with an inlet hopper.

Additional options of the mobile conveyors (specified when ordering in the Data Sheet upon agreement with the customer):

By motion mode:

- slides (skids);

- pneumatic-tire wheels;

- endless track;

- rail travel.

By mobility:

- self-propelled;

- non-self-propelled;

- transformers (for crossing automobile roads in the external dimensions of the road train).

Advantages of the belt conveyor

- Easy operation and maintenance of the transport system.

- Low specific cost including power cost.

- Possibility to safely transfer loads even with the significant inclination and at different angles.

- Low noise level.

- Controlled motion speed.

- Optimal dimensions for any room or site.

- Use of components supplied by reliable suppliers-partners ensure the continuous operation of the belt conveyor and the fast repair / replacement if required.

Main assembly units of belt conveyors

- Conveyor belt is the main and the most expensive element of the conveyor which acts simultaneously as a carrying and pulling mechanism.

- Idlers are intended to support the belt and shape it as required. For its intended purpose they divided into conventional and special ones.

- Tensioning devices put the belt under tension sufficient to transfer the pulling force by friction on the drive during steady-state motion and start of the conveyor. They limit the belt sag between the idlers, compensate the belt elongation resulting from its drawing during operation.

- The belt conveyor drive consists of a support frame of special design, drive and bend pulleys, gear boxes, braking devices, couplings, different equipment, etc.

- Support steel structures.

- Feed and discharge devices. Feeding and discharge of the belt conveyor according to the process requirements can be done in any point throughout the length of the belt.

- Devices for cleaning the belt and the pulley ensure the normal operation of the conveyor and increase the belt service life.

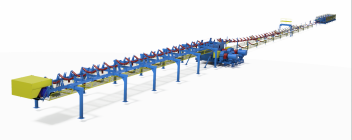

Stacker: optimal solution for handling and stacking loads.

The stacker or the telescopic belt conveyor very well solve problems of the companies where the bulk load storage is required. The elevating conveyor will help to stack the materials correctly.

The telescopic arm is boomed out by several tens of meters. The arm length adjustment allows operating the equipment in warehouses of different capacities and dimensions. As well as the stacker can be adjusted by length depending on a distance to the loading or unloading platform.

Other advantages of the telescopic belt conveyors: possibility to organize the continuous operation of the warehouse, to improve its capacity (when the stacker is used the warehouse capacity is limited with loader performance capabilities and a level of manual labor of load movers), to lift the load to a required height. The stacking — lines in a particular order or lines at multiple levels — protects the load, maintains its quality and helps to keep order at the warehouse. The stacker does not require many people for operation and maintenance.

We offer to purchase the telescopic belt conveyor on beneficial terms. For information on the manufacturing terms and conditions call us by phone +7 (8172) 20-90-16 or send a request to email: conveyor@npoakonit.ru.

Отрасли применения продукции