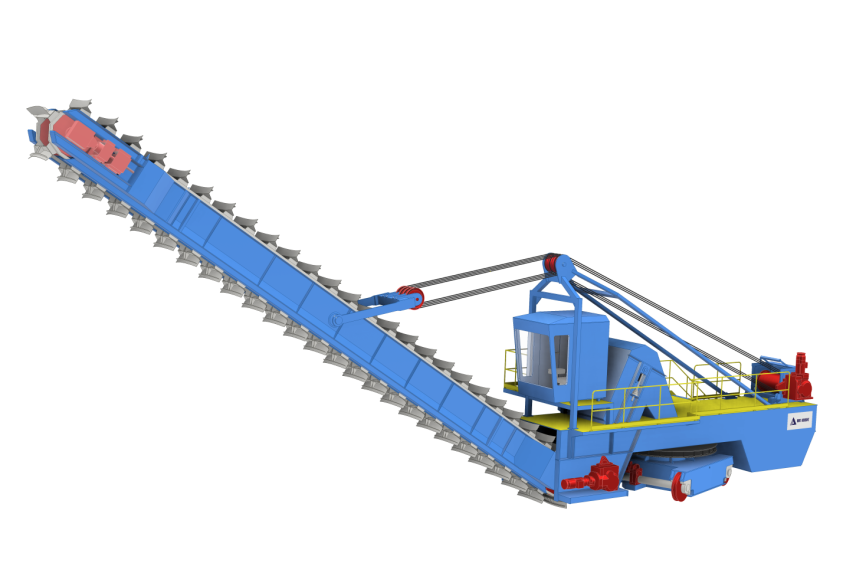

Cantilever reclaimer

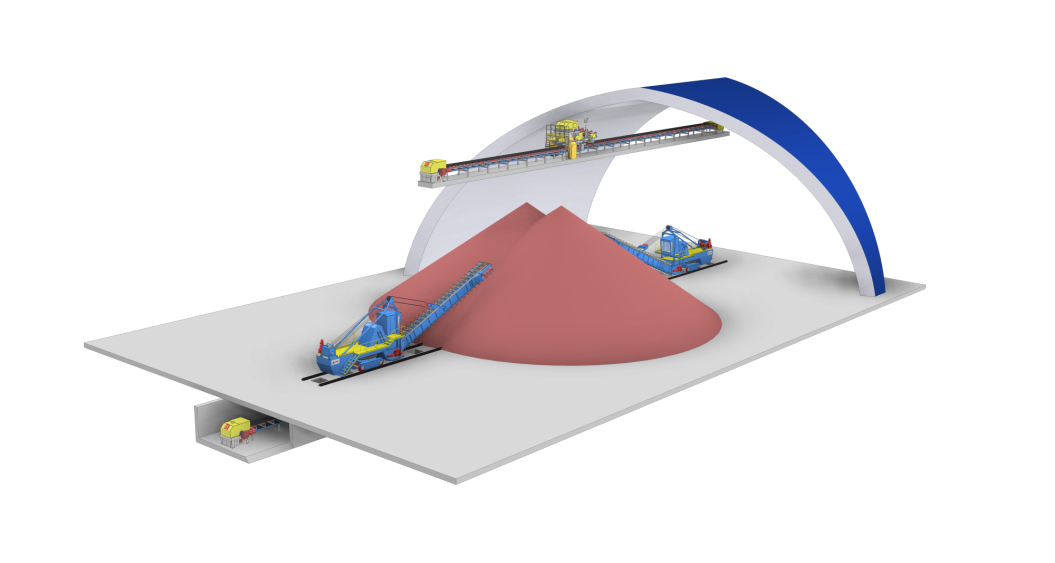

Closed truss warehouses are often used at enterprises for potash salts mining. Typical warehouses of small capacity - in the production of ammonium sulfate, mineral fertilizers and other chemical compounds. Given the compactness of this design, the equipment works in potash mines. In compliance with the norms and requirements, it is completed with explosion-proof components of electrical equipment. Such a warehouse has a maximum reclaiming capacity of 500 t/h. The stockpiling is carried out by the upper loop belt conveyor. Stockpiling is done using the cone method. With this stacking, homogenization of the product is not a priority, but when reclaimed from the end side, the stockpile is homogenized. The reclaimer moves along rails in the longitudinal direction of the warehouse and reclaims the material onto an underground conveyor through special hatches in the floor of the warehouse. The main structure of the reclaimer rotates 360 degrees relative to the rail track, which makes it possible to perform reclaiming with a maximum radius. By changing the angle of inclination of the scraper boom, the reclaimer reclaims the material from the stockpile to the zero level with rotary movements. The automated control system allows reclaiming in automatic mode. The participation of the operator is required only in some cases, for example, to change the program of reclaiming of a new stockpile or a stockpile with different physical and mechanical properties of the product.