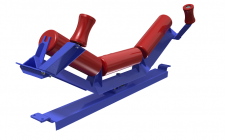

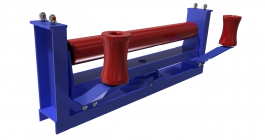

Troughed idlers (ZhG)

A troughed idler (ZhG) is a metal structure for mounting rollers on it.

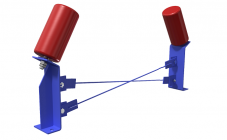

Idlers are one of the key structural elements in belt conveyors. They are used to support the rollers on which the belt moves and give it the necessary shape. The conveyor flight can be equipped with special idlers that automatically center the carrying and return branches of the belt. The idler can be made at the request of the customer with stamped legs, of a pipe, or of a channel.

Idlers are used to move large fractions of bulk materials: clay, sand, crushed stone, coal, etc.

Troughed idlers are available in two types - reinforced and lightweight design. The reinforced design of the troughed idler (ZhG) is for conveyors experiencing the greatest loads, and is characterized by increased rigidity and reliability of the structure. The structure is reinforced by the use of a channel. Various designs of the reinforced troughed idlers are possible at the request of the customer.

Industries of application:

Mining, coal, chemical industry, metallurgy and other industries that use conveyor transport.

Advantages:

All idlers by SIA "Akonit" are made using modern machinery, which ensures a high level of quality. Conveyor rollers "Akonit" are used in the idlers. They are designed for difficult operation conditions (heavy concentration of dust, high humidity, shock loads, high speed).

We impose strict control requirements on our products:

- Strict incoming inspection of the materials used;

- inter-operational control at all stages of the idlers manufacturing;

All this ensures high quality of products and a long service life of the rollers without breakage and replacement.

The price for the troughed idlers is determined individually depending on the terms of production and a batch. The price for the idlers may include delivery at the customer's request. Supplied both separately and as an assembly with rollers.

The material of the idler is steel St3. Other materials can be used at the customer's request.

Belt width - from 400 to 2000 mm.

Possible angle of inclination - 10, 15, 20, 30, 45 degrees. Increased angle of the side rollers increases conveyor performance and reduces the possibility of spillage.

Applied channel profile - Sh10, Sh12, Sh14, Sh16.

SIA Akonit offers several designs of the troughed idlers (ZhG).

When placing an order, the first thing to consider is:

conveyor width

flight width

the environment in which the equipment will be operated.

We are also ready to manufacture the idlers with the lengths to specific and non-standard requirements and requests.

Idlers for belt conveyors - what are they for?

Idlers are one of the key structural elements of belt conveyors. They support the rollers on the conveyor that the belt runs on. If necessary, they can give the belt the desired shape. The conveyor flight can be equipped with special idlers that automatically center the carrying and return branches of the belt.

How to purchase idlers for belt conveyors?

The best way is to contact directly to the manufacturer of components for belt conveyors, which has experience in the manufacture of this equipment.

SIA Akonit offers 10 types of idlers for stationary belt conveyors, including troughed idlers, centering troughed idlers, return flat and troughed idlers.

When manufacturing, the company pays close attention to the individual wishes of the customer and is ready to make idlers according to non-standard requirements, including material (for standard idlers it is steel St3), product length, etc. You can specify data for manufacturing by filling out a data sheet on the website, or by phone. +7 (8172) 20-90-87. The cost is determined individually, depending on manufacturing time and a batch. The price for the idler may include delivery at the request of the customer. The idlers are delivered both separately, and assembled with rollers for the conveyor.

Also, the equipment - components - of belt conveyors undergoes strict control at all stages of production, which ensures the quality of each batch of products and its stability. In addition, careful inspection is the key to the long-term operation of the idlers. You can be sure that we will do exactly what you need!