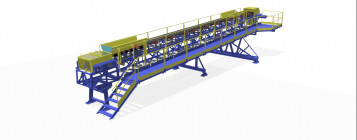

Underground belt conveyor

Underground belt conveyors are the most efficient types of continuous transport. The equipment length can reach several kilometers. When designing and manufacturing, the Company focuses on the main requirements to the belt conveyors in the mine — compact design, maximum explosion protection and high quality of rocks cleaning.

JSC “SIA “Akonit” is working to improve its design solutions and uses the latest technical developments for manufacturing of the wear-resistant conveyor equipment which can be operated under severe conditions.

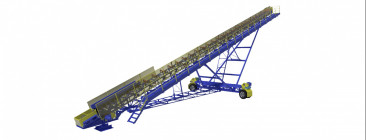

The Company has its own engineering developments of multi-level (cascading) conveyor systems that significantly improve the equipment operation. It is also possible to manufacture steel structures which are lightweight by 2–3 times as compared with standard steel structures. Therefore, the customer expectations to reduce the equipment weight are taken into consideration.

The main element of the underground conveyor is a belt. The belt is driven by a drive tension pulley. The underground belt conveyor configuration includes troughed idlers that ensure stiffness and integrity of the structure and minimize sagging under the weight of a load.

Underground belt conveyors are mainly used for drivage and works aimed at extraction of minerals including coal mining. They are also used during erection of underground structures and mining. Such type of equipment is indispensable for facilities where the periodical change of working length is required. For example, during the mine working. Underground belt conveyors are used in metallurgy, processing and power industries to transport coal, ores, fertilizers and other bulk materials.

The company has a great experience in designing and installing of the mine (underground) conveyors of different modifications: KLSh-800, KLSh-1000, KLSh-1200, KLSh-1400, KLSh-1600. More than 70 units of equipment with the total length exceeding 30 km have been produced over the years.

Advantages:

- Space saving — the Company has experience in manufacturing conveyors with the best possible length for customer specific applications

- Possibility to transport loads with different characteristics

- Availability of a special unit for the belt tensioning and cleaning

- Low power consumption

- Supporting frame stiffness, possibility to deliver overhead flights

- High capacity and smooth movement

- Framework flexibility, high unification that allows to reduce time for equipment production and delivery

- Maintenance of qualitative characteristics of the product

- Availability of components from warehouse (drive group, pulleys)

Do you need a conveyor for the mine?

High requirements are imposed for equipment used for load transportation in mines. Compact design, safety (same as explosion protection) and reliability are three principles to be satisfied by the conveyor used for coal transportation. These principles are imposed by limited space, impossibility to quickly leave the area of the conveyor operation and great difficulties of replacement of the conveyor components and assembly units. Therefore, the manufacturers are always on the lookout for new technical solutions to improve performances of the underground belt conveyors.

How is the reliable conveyor operation in the mine ensured?

JSC “SIA “Akonit” uses its own engineering developments of multi-level (cascading) conveyor systems that significantly improve equipment operation. It is also possible to manufacture steel structures which are lightweight by 2–3 times as compared with standard steel structures elements. Therefore, the customer expectations to reduce the equipment weight are taken into consideration. One of the latest development is a lightweight idler. Its weight is reduced by 33% as compared with a standard one. For mor information please visit our web-site, NEWS section.

The company has a great experience in designing and installing of the mine (underground) conveyors of different modifications: KLSh-800, KLSh-1000, KLSh-1200, KLSh-1400, KLSh-1600. Over the years more than 70 units of equipment with the total length exceeding 30 km have been produced.

For further details on conveyor components manufacturing process and for ordering the products please dial up +7 (8172) 20-96-16 or fill in a Data Sheet.

Отрасли применения продукции